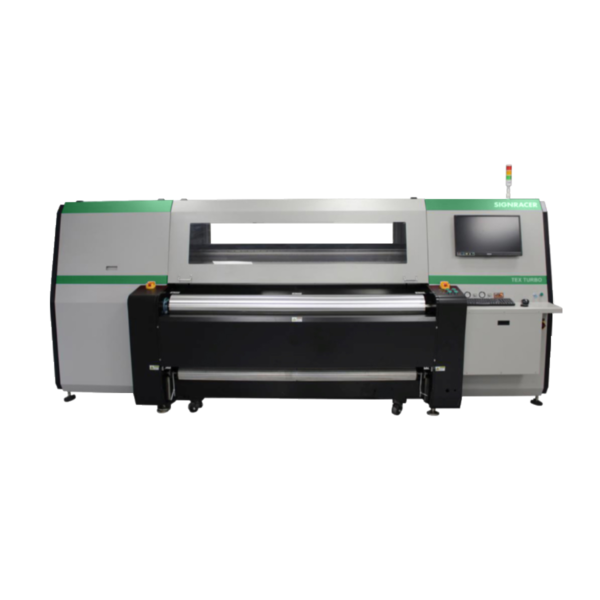

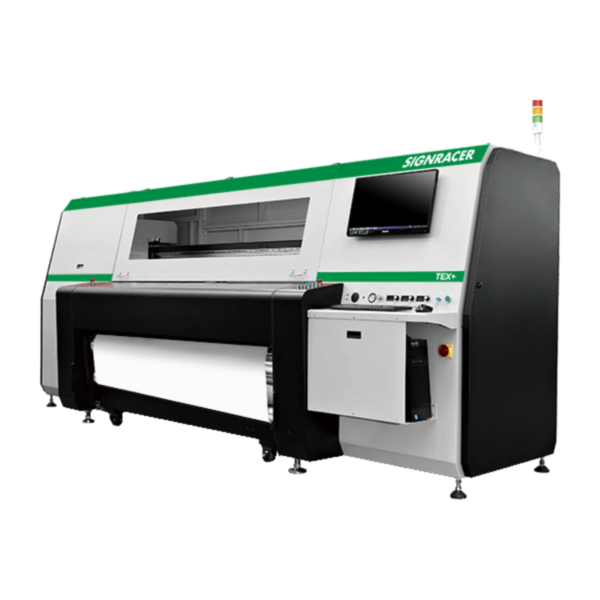

Descrizione

Costruzione ibrida sia per la stampa su carta transfer sia per la stampa diretta su tessuto con lo stesso inchiostro. Nessun compromesso.

Carrozza

Dotato di due testine di stampa Kyocera.

Stazione di tappatura

Pulizia automatizzata con due spazzole tergicristallo.

Pompe peristaltiche

Le pompe di livello industriale garantiscono un flusso di inchiostro regolare e stabile

Asciugatura ad aria calda

Due unità di asciugatura ad aria calda per una stampa stabile della carta.

Pannello di controllo frontale

Per un comodo controllo della tensione e della temperatura.

Velocità di stampa su carta transfer

Velocità di stampa Per Direct to Textile

Special hybrid ink

For Paper Transfer and Fabrics

- Combining direct disperse dyes and transfer dyes

- Fast drying characteristics for paper printing

- Larger colour gamut

- Good ink penetration with better light fastness

Removable Vacuum Plate

For Hybrid Printing

- Adjustable vacuum system for smooth transfer paper printing

- By removing we create an ink ditch for direct printing

- With ink absorption filters to collect ink

Easy Switching

2 in 1 Printing System

- Change from direct to transfer paper in 15 min.

- Transfer paper printing or Direct printing

- Super Easy

Take-up & Media Handling

Tension adjustable feeding and winding

- Pinch rollers for smooth media transport

- Optimal for transfer paper printing

- Vacuum print bed which can be adjusted by software to optimize media flatness and improve drop placement accuracy

Drying

Hot Air Drying Units

- Multiple hot air drying units

- Smooth and even drying of sublimation ink in high speed

- Suitable for high ink density on low paper grammage

Ready to Print

Capping and Cleaning Station

- Four wiper blades for automated cleaning

- Automated cleaning reduces downtime

- Special cleaning fluid for high performance and high stability

Print Head Protection

Media Jam Sensor

- Jam Sensor on both sides of the carriage

- Detects wrinkled media and prevents head strikes and media jams

- Ensures increased print head lifetime

Variable Droplet Printing

High Quality Printing

- High quality printing due to variable sized droplets

- Using drop sizes; 5,7 and 12 picolitre in all print modes

OBR

Optical Banding Reduction

- OBR (Optical Banding Reduction) prints passes in gradation-like tone by dispersing ink drops between the passes, which reduces banding, uneven drying of the ink and bidirectional stripe

- OBR can be set in the software in range

Inchiostri TEX

- Ottimizzato per la stampa diretta e su carta transfer

- Sviluppato per le testine di stampa Kyocera® KJ4B

- Eccellente efficienza di trasferimento

- Velocità di stampa più elevate per una maggiore produttività

- Eccellente affidabilità di stampa e gamma di colori superiore

- Asciugatura rapida per stampe ad alta velocità

- Disponibile in quattro colori CMYK

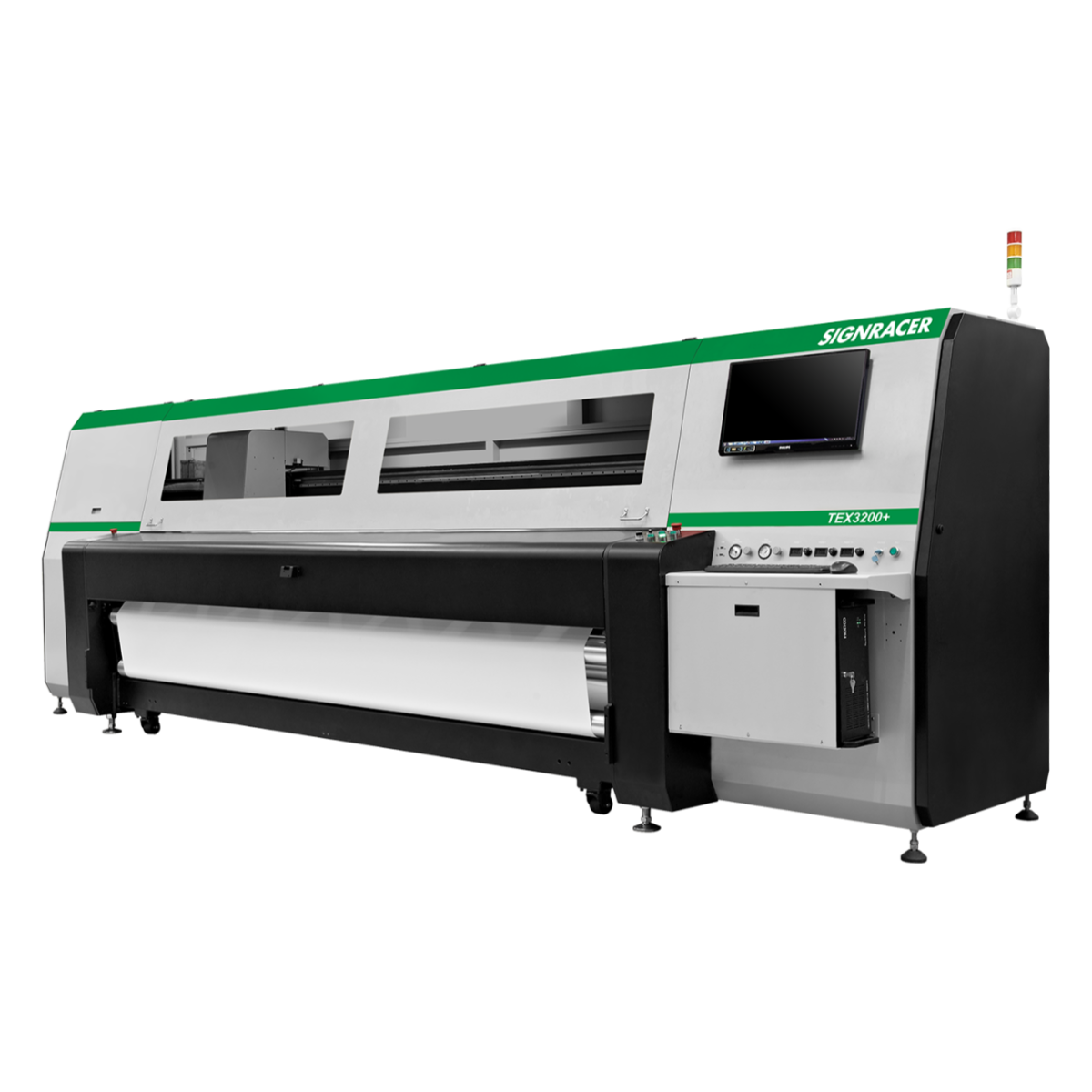

Print Heads

Kyocera KJ4B

4 Print Heads

Total 2,656 nozzles

Drop Size 5/7/12 pl

Grayscale

Printing

Maximum Printing Width 3300 mm

Carriage Speed 1.0 m/s

RTR (Roll-To-Roll)

Tension-adjustable continuous winding/unwinding control technology

Speed

Draft Mode 360 m2/h

Production Mode 265 m2/h

Quality Mode 180 m2/h

Dimensions

Length x Width x Height

5600 x 1550 x 1900 mm

Weight 2600 kg

Requirements

Printer and Heater Power 23 kW

Power Supply AC 380V/ 220V

Compressed Air 0.6MPA / 0.15m3/hr

Media

Transfer paper & Polyester textiles

Max. Media Width 3350 mm

Media Thickness Maximum 2 mm

Max. roll weight 200 kg

Inks

Signracer TEX

Available Colours CMYK

Ink Package 5 L bottle

Main Ink Tank Capacity 10 L with level sensor